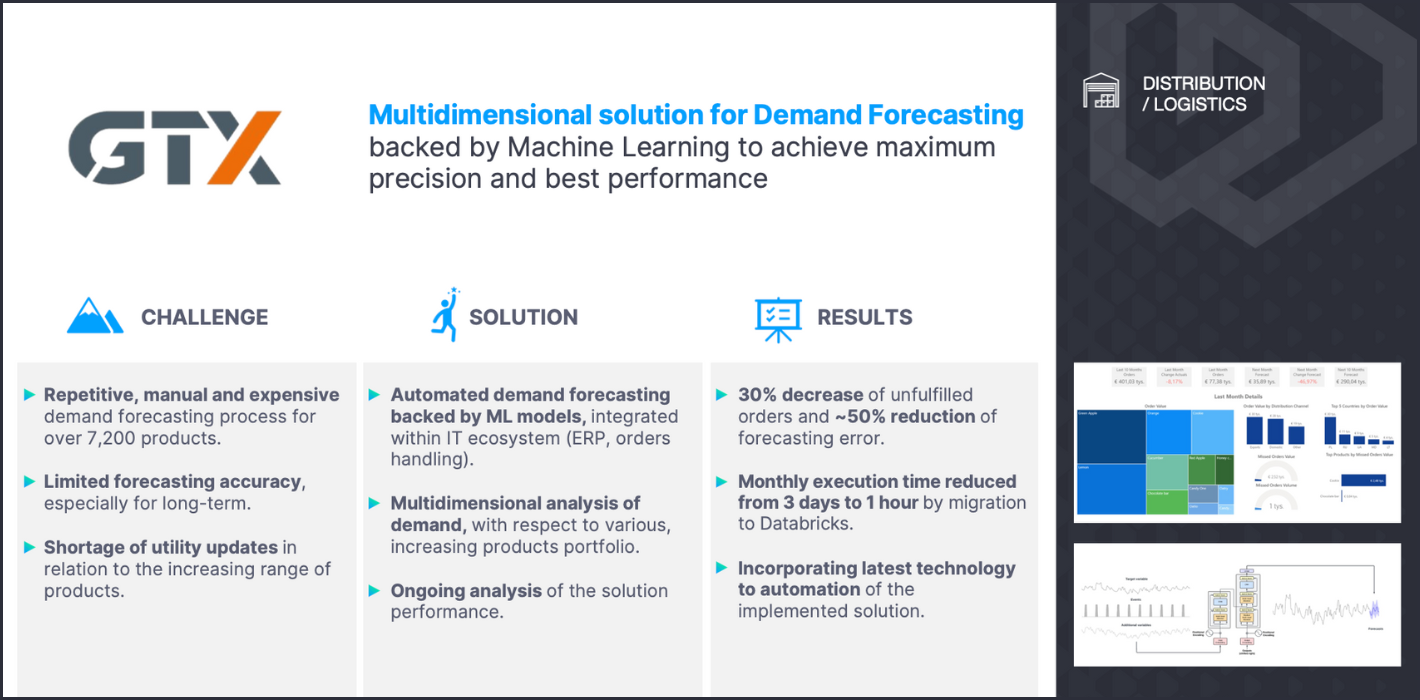

The client

GTX Group is a Polish leader in the hardware industry, offering customers a diverse range of tools and power instruments. The company portfolio incorporates 5 in-house brands with more than 7,200 products in 40 countries.

With an extensive distribution structure, GTX manages three international companies in China, Ukraine and Romania, employing 600 multinational people. To ensure the ongoing quality of the product portfolio, the company conducts more than 100 quality tests based on European Standards for around 300 product groups.

The challenge

Every month, the forecast department of the GTX Group, based on its expert knowledge, market analysis, trends, weather, and number of construction sites in the country, had to manually forecast the necessary stock level for each of its products to meet the demand in the following months. The process required the maintenance of a team of highly skilled experts, which resulted in high operating costs.

Effective demand forecasting has emerged as a struggle with the passing of the COVID-19 pandemic period severely disrupting the supply chain. The crisis has prompted companies and suppliers to re-examine purchasing patterns and the way of forecasting and managing logistics. In addition, the supply chain’s stagnation and the sales industry’s lack of predictability have also contributed to the reduced functionality of the deployed processes.

Key pain points:

- Forecasting the demand for over 7,200 products concerning a range–specific approach.

- The inability of the utility and the market demand was caused mainly by the global pandemic.

- Uncertainty in the supply chain disrupts the prediction of demand.

- Many constantly changing factors and parameters, such as historical sales trends and seasonality.

The solution

After thorough testing, we chose an analytical specialized framework available under an open-source license. BitPeak took advantage of the configuration options to adapt the most optimal mathematical model to the specifics of GTX Group sales. Forecasts are generated for the next 10 months, while direct recommendations are made for the next month.

We used the cloud as a base for our solution to ensure its scalability. The great advantage of the cloud is the ability to run many servers just for the duration of the task – providing great flexibility. Thanks to this approach, we have reduced the forecast calculation time to 2-3 hours instead of several days.

Considering the span of the COVID-19 pandemic and its impact on the supply chain, an evaluation of the implemented framework was performed. By offering a partner attitude approach, we focused on monitoring deployed solutions that were possibly affected by external factors.

After establishing the quality of the existing framework, we addressed the need to implement new functionalities, focusing mainly on improving the forecasting process concerning the client’s increasing portfolio. Additionally, the potential update includes product-specific demand forecasting and prediction of multi-time series.

To realize our goal, we used the following tech stack:

- Databricks: for application deployment

- Azure Data Factory: for data processing and preparing pipelines through which the prediction generation process is triggered

- Azure Key Vault: application security verification

- SQL Server: on-prem database

- Azure Blob Storage: data in-cloud storage

Benefits:

Sales

The forecasting process was fully automated and supported by innovative technology, eliminating human error and reducing monthly execution time to just 1 hour. This reduced the repetitive and labour-intensive task of providing recommendations to all 7,200 products and allowed the department to focus on unique and uncommon cases, increasing its efficiency.

Strategy

Thanks to our solution, forecasting errors were reduced by 50%, which resulted in 30% fewer unfulfilled orders – not only increasing revenue but also improving the reliability of GTX as a supplier. This, in turn, improved its image as a business partner and as a brand, causing an upturn in the number of future contracts.

Partnership

Partnering with BitPeak provides the client with ongoing maintenance and optimization of the implemented solution, even after the project runs its course. By developing the proposed upgrade, our client would enhance the efficient forecasting process and significantly increase the framework’s functionality.

(+48) 508 425 378

(+48) 508 425 378 office@bitpeak.pl

office@bitpeak.pl