The client

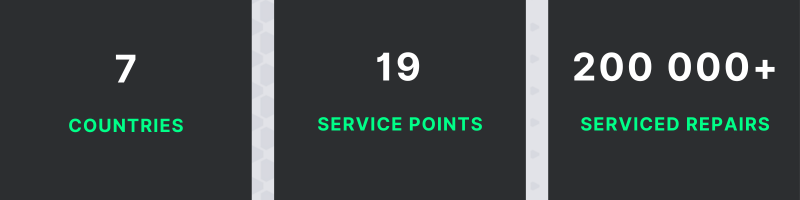

GTX Service provides a comprehensive after-sales service, filling the space between users, shops, service technicians and brand owners of the equipment under repair. Their portfolio includes services in the areas of power tools, battery-powered, diesel or pneumatic equipment.

The company also services scooters, skateboards or electric bikesand is highly engaged in carbon footprint reduction. Last year alone, repairs carried out by GTX Service reduced CO2 emissions by 411 tons, which is equivalent to planting 56,000 trees.

GTX Service provides services related not only for brands from the Topex group but also other companies such as Bosch, Husqvarna and Makita. The company cooperates with large retailers such as Castorama and Leroy Merlin. Every customer that returns the product or hands it in for repair at one of the aforementioned chains actually hands it over to GTXService.

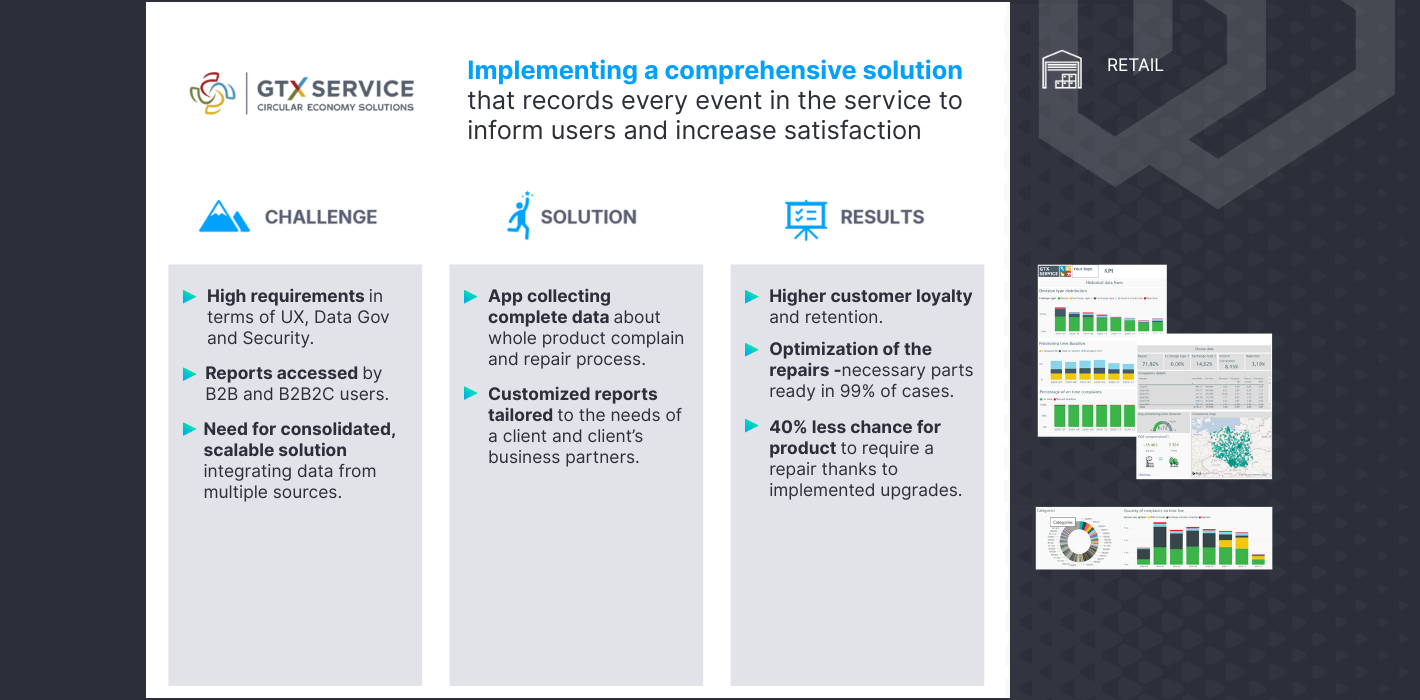

The challenge

The client needed BitPeak’s help in raising the quality of their customer service. The goal was to grow customer loyalty by increasing satisfaction with the speed and quality of the repair process. Additionally, the system was supposed to collect and process data about each stage and activity during the complaint process, repair and damage of each product. Through that, the algorithm provided a wealth of information about customer expectations and possible faults in the construction or design of client’s products.

An additional challenge was conducting the design, implementation and integration phase quickly to minimize the inconvenience to the customers and client partners.

- The significant amount of processed products and complaints

- Necessary speed of implementation – we managed in just 4 months

- Processing details about each stage of the complaint process and providing actionable insights

The solution

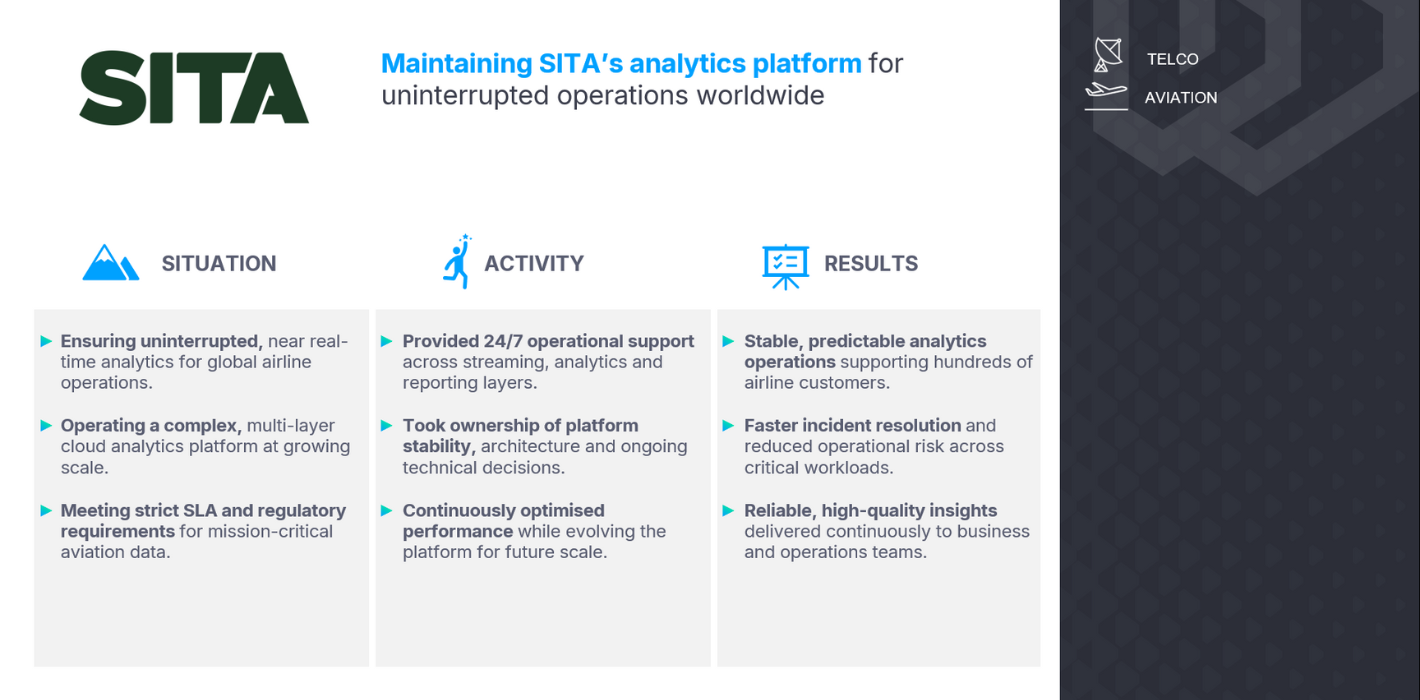

As part of our solution, a data warehouse was built based on an SQL Database in Azure to which data from the Webcon system is transferred every few hours using the Azure Data Factory service. The SQL Database is then the data source for the data model in Power BI. Users of the system get access to the data through individual accounts in Power BI that identify them within the organization (e.g. Castorama), which personalizes the look and feel of the user interface as well as the scope of the data and relevant policies. As we have information on all networks in one database, the aspect of personalization, security and visibility of relevant data was strongly accepted by the client.

The entire environment is maintained and managed using the Azure DevOps environment, which allows for automation and proper management of the solution code in terms of Continuous Integration and Continuous Delivery, minimizing the risks associated with version management and the change implementation process.

An interesting example of a dashboard is the visualization of the reduction of CO2 emissions through the use of GTX Service and the repair of hardware instead of replacing it with new hardware.

Today, at all of the company’s service points in Poland and Europe, employees use an app to guide the service process step by step. From registration through transport, diagnosis, repair, testing, packaging and return transport to the customer. In this way, they record huge amounts of data and take photos of repairs, damage and also record the demand required for the spare parts procurement processes. Power BI reports can be viewed not only by the company’s employees, but also by the owners of the brands it works with.

To realize our goal, we used the following tech stack:

- SQL database: for the Azure-based data warehouse construction

- Azure Data Factory: for data processing and preparing pipelines through which data from Webcon system is transported to the Data warehouse

- PowerBI: for presenting data in the form of simple but informative, user-friendly reports and dashboards

- Azure DevOps: for maintenance and management

Benefits:

Sales

Thanks to information provided by our system one of our contractors reduced the complaint rate of his products by as much as 40% within 3 years through targeted improvement of the weak points of his equipment. In doing so, he saved millions of dollars a year in after-sales service!

Customers

Our system increased the efficiency and speed of the complaint procedures and allowed customers to track its progress which allowed us to reduce negative outcomes and provide better experience to the users.

Operations

Demand for parts and images of all technical diagnoses are recorded on the proprietary service platform damage types. This data can be shared through clear Power BI reports, with business partners, including Leroy Merlin, Grupa Topex or CMC (supplier of Lidl Polska) allowing for possible monetization and better business relations.

(+48) 508 425 378

(+48) 508 425 378 office@bitpeak.pl

office@bitpeak.pl